By using seetrudirect.com you agree to our use of cookies to enhance your experience.

Tuesday September 16, 2025

| +44 (0) 117 930 6100info@seetru.com |

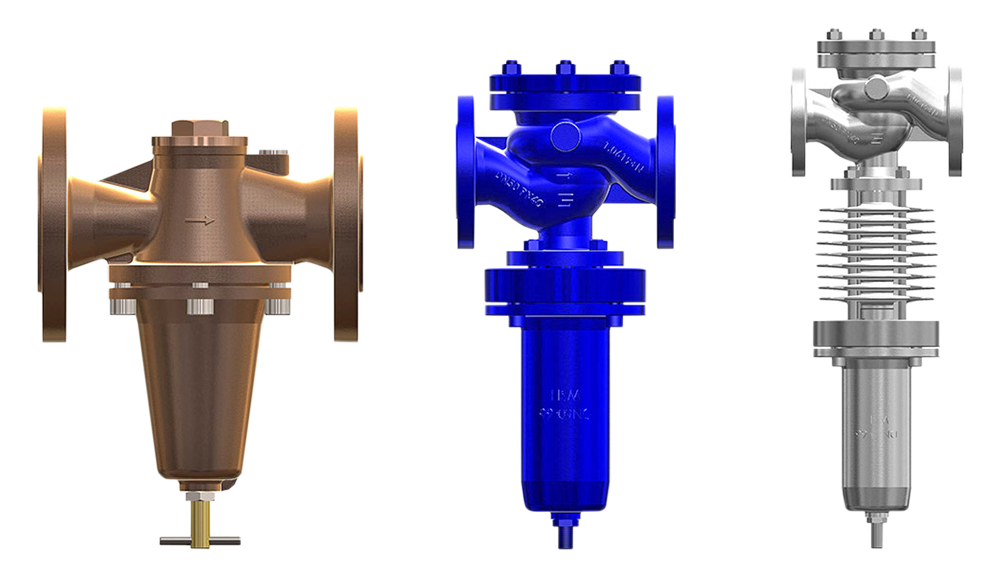

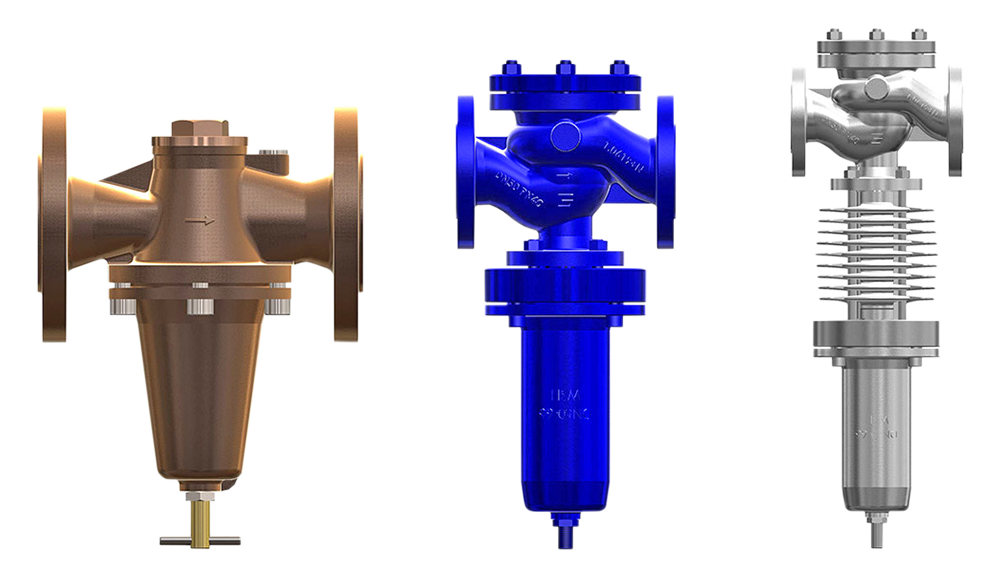

Pressure reducing valves - from SCHLEY ARMATUREN GMBH

For industrial, chemical, steam and oil & gas applications.

Connections: From DN15 to DN200 (1/2" to 8")

Outlet Pressures: From 0.5 to 40.0 bar

Materials available:

- Ductile cast iron 0.7040

- Cast steel 1.0619

- Stainless steel 1.4408

- Bronze CC480K (GbZ10)

- Aluminum bronze CC333G

- Super Duplex 1.4469

The function of pressure reducing valves (pressure regulating valves) is, to reduce a varying or constant upstream pressure (inlet pressure) of the media to a constant reduced pressure (outlet pressure, back pressure) which is depending of the upstream pressure.

The pressure reduction occurs by throttling the free cross section between the seat and the cone. Any change in pressure on the downstream pressure side is immediately converted into a lifting movement of the valve cone.

At zero consumption, that is, when the consumption on the downstream pressure side is zero, the valve doesn’t close tightly.

The pressure reducing valves are suitable for compressible media, e.g. compressed air, natural gas, nitrogen, as well as for incompressible media, e.g. water, oil, fuels, LPG (propane, butane) etc.

They are mainly used in industrial plants, plant engineering and process engineering.

Pressure reducing valves can be supplied with flanges, weld ends or threaded connections.

Contact Seetru for more information and to receive a quotation!

Schley All Products |  Steam Applications |  Chemical Applications |  Oil & Gas Applications |

All Schley Products: Click here to view the All Schley Products.

Schley Products for the STEAM Industry: Click here to view the Schley products for the STEAM Industry.

Schley Products for the CHEMICAL Industry: Click here to view the Schley products for the CHEMICAL Industry.

Schley Products for the OIL & GAS Industry: Click here to view the Schley products for the OIL & GAS Industry.

Schley Products for the STEAM Industry: Click here to view the Schley products for the STEAM Industry.

Schley Products for the CHEMICAL Industry: Click here to view the Schley products for the CHEMICAL Industry.

Schley Products for the OIL & GAS Industry: Click here to view the Schley products for the OIL & GAS Industry.

|

Copyright © 2024 Seetru Limited. All Rights Reserved.

Basket

Basket  Home

Home